Each metal stamping manufacturing process uses different physical processes to form metal parts. Some of the most commonly used metal stamping processes include:

Metal stamping is a category of manufacturing that uses cold-forming processes to create metal parts with distinct shapes out of metal sheet or coil stock. There are multiple different metal stamping techniques, but all use some combination of sharp tools and pressure to cut parts out of sheet metal, create cut-outs in metal pieces, or add marks or textures to metal. Metal stamping techniques are used to create precise two-dimensional pieces and as well as transform sheets into three-dimensional parts.

Below, we’ll discuss the different metal stamping process techniques, various types of metal stamping, and how metal stamping performs in comparison to other manufacturing techniques.

Metal Stamping Processes

- Punching: Punching creates holes in workpieces using a punch press to force the punch tool through the sheet metal. This process creates holes in the metal sheet and deposits the scrap slug into the die below the sheet metal.

Punching is typically a cold-forming process, but it can be used in some hot applications. This is one of the most cost-effective metal stamping techniques available. The process itself is inexpensive and fast enough to create savings for most manufacturing projects. - Blanking: Blanking is an intermediary step to improve the efficiency of other stamping and finishing operations. During the blanking process, a metal form (or blank) is cut from a sheet with a rough outline that aligns with the end design. By taking this intermediary step, manufacturers minimize the risk of burrs developing in later stages.

- Embossing: Embossing is a cold-forming process used for creating specific formations or designs on metal pieces. Male and female embossing dies press a workpiece between them with sufficient force to impart three-dimensional designs onto the surface.

- Coining: Coining is a forming process that uses an extreme amount of pressure to push the workpiece into a die. The die then forms the metal into a precise shape and creates permanent forms in the workpiece. Coining also smooths the edges of metal parts by striking them with a high degree of force. This removes existing burrs and hardens the metal. Coining may reduce the need for deburring, grinding, and other secondary processes at the end of the project, which saves both time and money.

- Bending: Bending processes transform metal sheets and two-dimensional workpieces into three-dimensional pieces. Bending occurs through multiple mechanisms. In some processes, one edge of the workpiece is clamped in a stationary position while the other edge is clamped by a metal tool and bent over a die to create a precise bend or shape. Alternatively, the metal piece may be pushed into or against a die.

When bending, it’s important to consider the plasticity of the metal, as each metal stamping material type can only handle a certain amount of bending before cracking or weakening. Many metals also harden under stress and can react poorly to too much bending. Metal pieces also typically need to be bent along the direction of their grain lines. This allows the metal to stretch and accommodate the bend instead of splitting and cracking between grain lines. - Flanging: Flanging processes bend metal tabs and parts on workpieces at a 90-degree angle. Unlike general bending processes, flanging applies only to small tabs and portions of an overall workpiece. Flanging may sometimes be incorporated into custom dies used in other stamping processes to save time and expense.

Types of Metal Stamping

There are a variety of metal stamping methodologies that may incorporate one or more of the above processes. Some of the most common metal stamping techniques include:

Types of Metal Stamping

There are a variety of metal stamping methodologies that may incorporate one or more of the above processes. Some of the most common metal stamping techniques include:

-

Progressive Die Stamping

A progressive die is a single die that captures one or more fabrication steps for the workpiece. The workpiece is carried through a series of stations until the final part is cut from the raw material at the final step.

For example, the first portion of a progressive die might punch holes into the workpiece, and the second step will then press the workpiece into a V-shaped form. These dies are economical, easy to use, and save significant time for designs that require more than one type of stamping operation. Progressive dies are the most common type of die.

-

Deep Drawn Metal Stamping

Deep drawing is a technique used on a variety of metals, including brass, copper, nickel, and stainless steel. This stamping process uses the same technique—typically a drawing action—repeatedly on the same workpiece to transform a flat strip of metal into a part with a deep recession, such as a hollow cylinder. In some cases, each action further recesses the part until it reaches its specified depth.

-

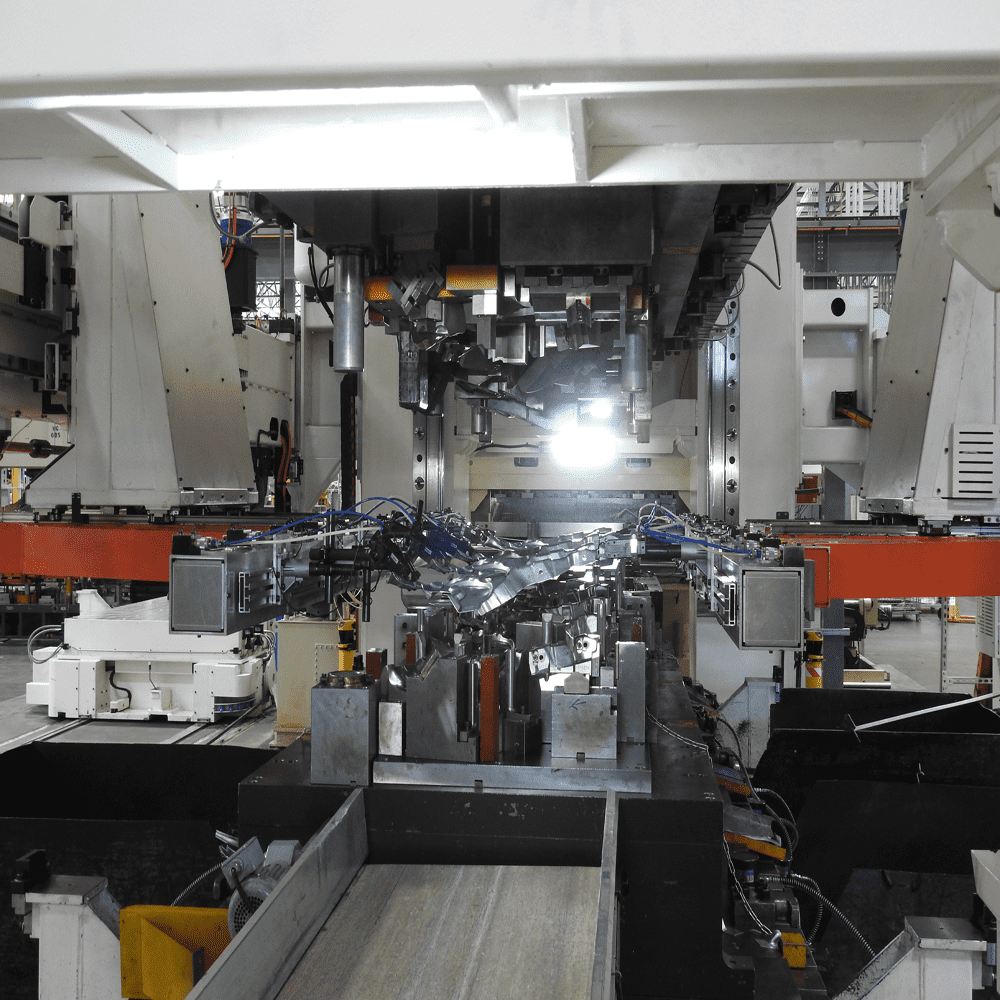

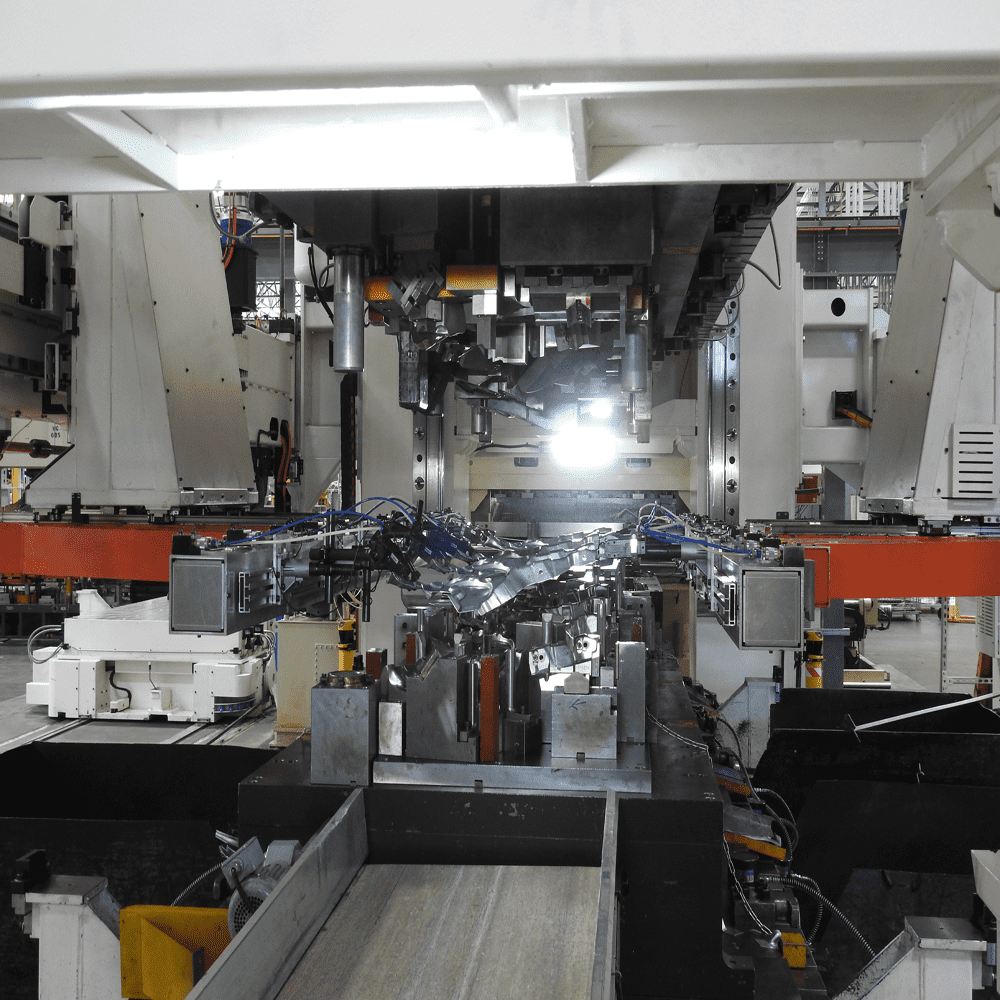

Transfer Die Stamping

Unlike progressive die stamping, which relies on a metal strip to pull the part through various stamping stages until it is cut free on the final step, transfer die stamping removes the in-progress part from the strip and moves it between stamping stations using a mechanical transport system. This process is useful for designs where the metal strip may interfere with complex design features such as pierced holes, cut-outs, threading, ribs, or knurls. It may also be used for parts that are too large for progressive die stamping.

-

Multi-Slide Metal Stamping

Multi-slide metal stamping is reserved for parts with several bends or complex portions. Four-slide or multi-slide stamping shapes several areas of the workpiece simultaneously. This process is often used to create parts with a continuous bend, such as coils.

Explore different metal stamping methods with Aranda Tooling, including progressive die, transfer die, and deep drawn metal stamping.

Comparing Metal Stamping with Other Production Methods

Compared to other competitive manufacturing categories, metal stamping is often the superior choice.

Metal Stamping vs. Die Casting

Die-casting processes start with molten metal. The fluid is forced into a mold under pressure. There, the metal cools and hardens into a determined shape. This process only works with non-ferrous metals and can also be very expensive and time-intensive.

Metal stamping forms sheets of metal to create specifically shaped parts. Metal stamping also works with both ferrous and non-ferrous metals. However, stamping may have fewer options in terms of complexity and thickness. Each method brings unique advantages depending on the product design.

Metal Stamping vs. Laser Cutting

Laser cutting is another popular process for cutting away excess material from workpieces. It results in smooth edges and extremely accurate adherence to the original design. However, the heat of the laser can affect steel workpieces depending on their thickness and the tolerances required. Laser-cutting services can’t bend or form the metal, so the workpiece may end up requiring additional processes. For three-dimensional designs, metal stamping can offer a more comprehensive completion of the individual steps. Metal stamping can also handle thicker workpieces and parts made from a wider range of metals. Depending on the design of the part being constructed, as well as the materials required, one manufacturing method may be a better option than the other. Aranda Tooling offers both and can provide advice on which method would be best for your project.

Metal Stamping at Aranda Tooling

Aranda Tooling specializes in providing comprehensive metal stamping services for industrial clients. Our facility has over 50 punch presses that handle up to 1,300 tons, and our press bed works with parts that have dimensions up to 240 inches by 70 inches. We work with a variety of metals, alloys, and specialty metals like Inconel.

We’re proud to serve the following industries:

- Automotive

- Appliances

- Home hardware

- Power

- Medical device components

Visit our metal stamping services page to learn more about our design services, project management, quality assurance programs, Production Part Approval Process (PPAP), and variety of metal stamping capabilities. Please contact us or request a quote today for more information about our metal stamping capabilities and other services.

What is a Stamping Die?

A stamping die is a unique tool used to cut and shape sheet metal into a specific form. These dies are often developed using CAD software and analytical programs to create unambiguous and highly accurate designs. Experienced diemakers then use the designs to create the stamping dies. The dies are mounted in presses and used to produce parts from sheet metal.

The cutting and forming sections of the die are usually made from hardenable steel called tool steel, but they can also be made from other hard, wear-resistant materials such as carbide.

Types of Die Stamping Functions

Stamping dies are used for two main purposes: cutting and forming. Some dies can perform a combination of the two.

Cutting

Cutting, also known as shearing, is the process of using force to separate a piece of metal. This is typically done by applying enough pressure to the metal to cause it to fail or break along the desired line. Cutting is an important step in many metalworking processes, as it allows manufacturers to create parts with precise dimensions and shapes.

Cutting dies use the following techniques:

- Punching

- Blanking

- Embossing

Forming

Forming dies are used to shape metal by compressing it into a specific form. These dies are similar to stencils in that they have a specific shape or profile to which the metal is forced to conform. Forming dies are commonly used in a variety of metalworking processes to create parts with precise dimensions and complex shapes.

Forming die techniques include:

- Bending

- Flanging

- Coining

Manufacturing Tools for Stamping

Some of the most commonly used tools in the metal stamping process include:

- Tool & die-making equipment: Dies are created using CNC machines, EDM machines, lathes, mills and grinders.

- Metal stamping presses: These are used to apply pressure to the die and sheet.

- Secondary operation equipment: Many machines are used for secondary processes such as part straightening, deburring, and cleaning.

Request For

Request For